In the age of specialized architecture and smart infrastructure, custom elevators have become essential in modern building design. Unlike standard lifts, custom elevator solutions allow for precise adaptations to space, purpose, and aesthetics—offering tailored functionality in residential, commercial, medical, and industrial buildings. This guide outlines the key considerations and innovations surrounding custom elevators today.

Today’s intelligent building systems rely on seamless interoperability—and custom elevator solutions are designed with this integration in mind. Elevators can interact with access controls, emergency systems, and facility-wide automation platforms to enhance both user experience and operational efficiency.

Key integrations include:

Today’s intelligent building systems rely on seamless interoperability—and custom elevator solutions are designed with this integration in mind. Elevators can interact with access controls, emergency systems, and facility-wide automation platforms to enhance both user experience and operational efficiency.

Key integrations include:

Custom Elevator Design for Unique Building Layouts

Not every building follows conventional design norms. Many historic, mixed-use, or high-density structures require elevators to be adapted to non-standard shafts or floor heights. Custom elevator design addresses this need by adjusting dimensions, speed, and cabin layout. For example:- Narrow shafts may call for compact cabins under 1000mm wide.

- Unusual ceiling heights or split-level floors may require custom travel ranges or stopping precision.

- Panoramic glass elevators may follow curved or diagonal paths for aesthetic effect.

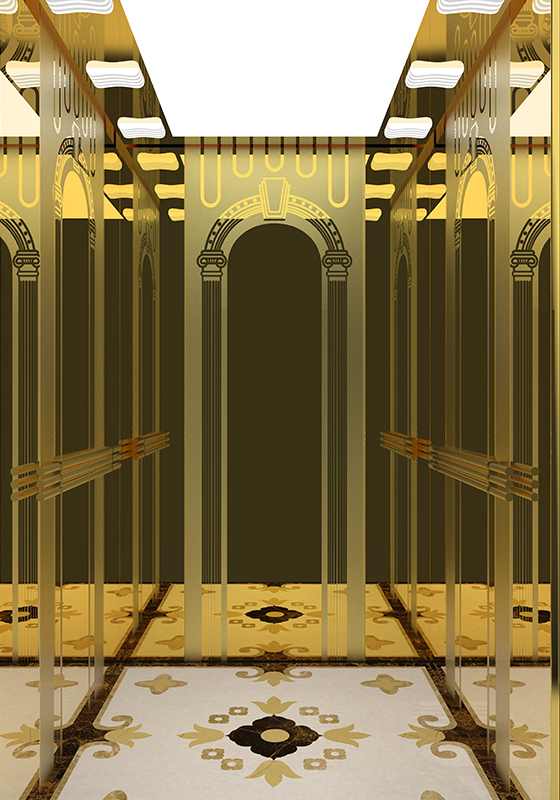

Custom Elevator Cab Interiors and Finishes

The interior of a custom elevator plays a major role in the user’s perception of the building. A carefully designed cabin can enhance the overall ambiance while aligning with architectural intent. Typical cabin customization options include:- Brushed metal, stone veneer, or tempered glass wall panels

- Ambient LED lighting, often dimmable or color-adjustable

- Personalized floor indicators, touchscreen displays, or multilingual announcements

- Floor materials compatible with building acoustics or hygiene needs (e.g., hospital vinyl or textured stone)

Custom Elevator Performance Tuning

A major advantage of using a custom elevator system is the ability to fine-tune performance specs. This includes:- Speed adjustments based on travel distance (e.g., 1–4 m/s for mid-rise; up to 7 m/s in skyscrapers)

- Ride comfort controls through smooth acceleration/deceleration curves

- Load capacity matching from light-duty home lifts (250–400 kg) to heavy-duty freight elevators (2000+ kg)

Custom Elevator Integration with Smart Building Systems

Today’s intelligent building systems rely on seamless interoperability—and custom elevator solutions are designed with this integration in mind. Elevators can interact with access controls, emergency systems, and facility-wide automation platforms to enhance both user experience and operational efficiency.

Key integrations include:

Today’s intelligent building systems rely on seamless interoperability—and custom elevator solutions are designed with this integration in mind. Elevators can interact with access controls, emergency systems, and facility-wide automation platforms to enhance both user experience and operational efficiency.

Key integrations include:

- Access control systems (e.g., RFID badges, mobile credentials)

- Fire alarm interfaces for automated recall

- Building energy dashboards for tracking elevator usage and performance

- Remote diagnostics that flag issues before breakdowns occur

Custom Elevator Sustainability and Energy Use

Sustainability is a growing focus in vertical transportation. Many custom elevator models now incorporate advanced energy-saving technologies:- LED lighting with occupancy sensors

- Lightweight car materials to reduce motor load

- Braking systems that recover motion energy and repurpose it internally

- Gearless traction systems that reduce mechanical inefficiencies

Custom Elevator Safety and Compliance Considerations

Regardless of design complexity, a custom elevator must meet regional safety codes such as EN 81, ASME A17.1, or local building regulations. Key safety features include:- Overspeed governors

- Bi-directional braking systems

- Emergency lighting and intercoms

- Automatic rescue device (ARD) in case of power failure

Custom Elevator Installation and Lead Time Planning

Customized vertical transport requires deliberate preparation. The coordination of technical drawings, fabrication, and approvals can extend the installation timeline. Lead times range from 10–16 weeks, depending on cabin complexity, shaft design, and code inspections. To stay on schedule:- Aligning mechanical plans with elevator specs must happen in the early architectural phase.

- Modular components or pre-assembled sections can speed up on-site work.

- Documentation (wiring diagrams, load specs, code certificates) should be finalized well before construction milestones.

- Planning for long-lead items such as custom doors, fixtures, or finishes can help keep projects on track.